Intermittent bagmaker ES400

Built to withstand the harshest washdown procedures, the VikingMasek ES400 VFFS machine has a superior hygienic design and rugged construction. This state-of-the-art vertical bagger features slanted electrical and pneumatic cabinets, fully stainless steel construction, and an open design for ease of cleaning. We understand the need for lean maintenance and low cost of ownership; that's why we never use proprietary parts. We blend just the right amount of technology and functionality, making our ES400 an unparalleled packaging solution in both construction and value!

max. 100 bags/min

max. 400 x 600 mm

min. 100 x 100 mm

Machine description

Built to withstand the harshest washdown procedures, the VikingMasek ES400 VFFS machine has a superior hygienic design and rugged construction. This state-of-the-art vertical bagger features slanted electrical and pneumatic cabinets, fully stainless steel construction, and an open design for ease of cleaning. We understand the need for lean maintenance and low cost of ownership; that's why we never use proprietary parts. We blend just the right amount of technology and functionality, making our ES400 an unparalleled packaging solution in both construction and value!

Machine features

- Siemens or Allen Bradley control system

- Robust, fully stainless steel 45° angled frame

- Stainless steel film unwind

- Servo-drive jaw actuation

- Two separate IP66 electrical and pneumatical enclosures

- Drip pan

- Off-the-shelf components

- Minimal maintenance requirements

- Easily-accessible, open design

- No tool change-over

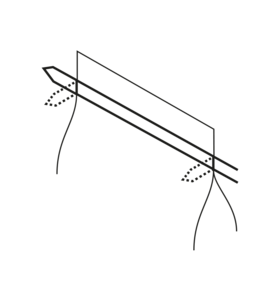

- Self-centering pull belts

- Automatic film tracking

- VFD powered film unwind

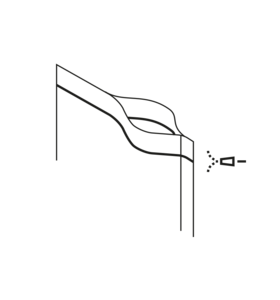

- Quick film splice table

- Product stagers

- End-seal cooling air

- Bag deflators

- Photo eye and encoder

- Jaw obstruction detection

- Stainless steel guard doors

- Runs most film structures

- Storage for 100 product recipes

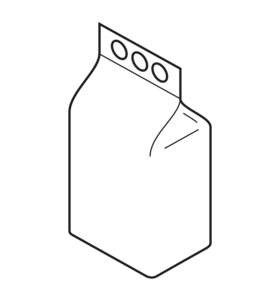

Pillow

Pillow

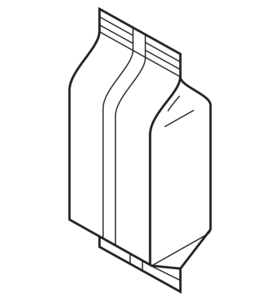

Gussetted

Gussetted

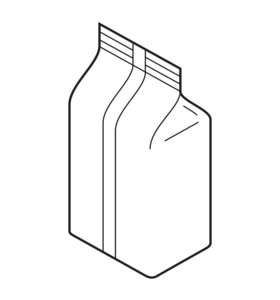

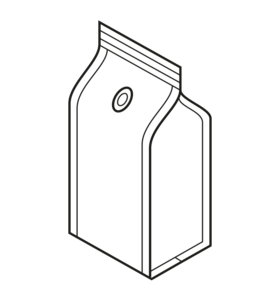

Flat bottom

Flat bottom

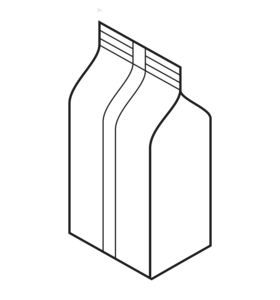

Corner creased

Corner creased

3-side sealed

3-side sealed

Zip

Zip

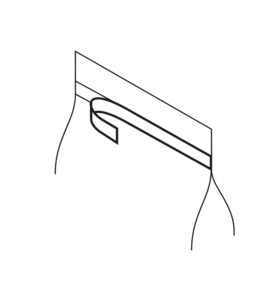

Tin tie

Tin tie

Label

Label

Resealable tape

Resealable tape

Finger grip

Finger grip

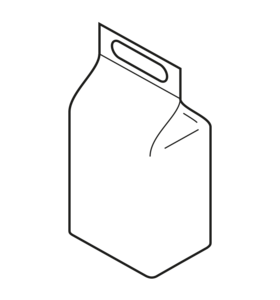

Carry handle

Carry handle

Degassing valve

Degassing valve

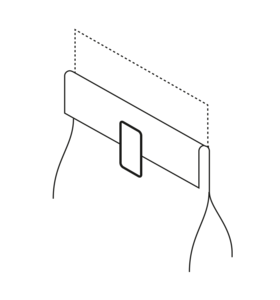

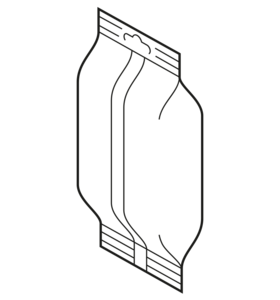

Euroslot

Euroslot

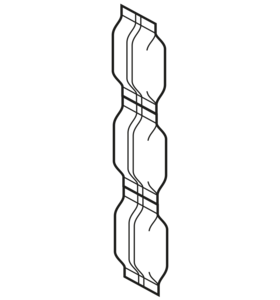

Chain bag

Chain bag

- Flat bottom bag assembly

- Integration with variety of fillers, printers, metal detectors, label applicators, and checkweighers

- Vacuum pull belts

- Hole punch (Euroslot and Round)

- Carry-handle punch

- Load shelf

- Product settler

- Gas flush

- Static eliminator

- Tear notch

- In-feed and take-away conveyors

- Remote diagnostics

- Squeegee system for packaging of liquids

- Air consumption: 100

- Bag size max.: 400 x 600

- Bag size min.: 100 x 100

- Max. speed: 100