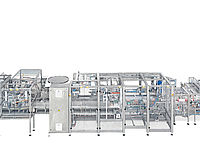

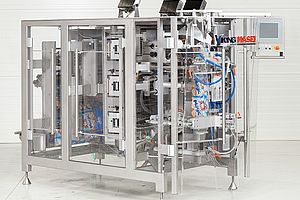

Intermittent bagmaker MS300

Meet the MS300. Highly flexible, reliable and incredibly fast bagger. Designed for packaging perfection, this bagger combines the ultimate technology, ruggest stainless steel construction and sanitary design. With speeds up to 150 bags per minute, faster, repeatable and accurate production runs will be the standard. Want consistency? The MS300 prevents bottlenecking, assuring all jobs will be steady. Want flexibility? The MS300 accommodates most bag styles, including block bottom, quad-seal and doy-style bags. Want peace of mind? Make the MS300 your next investment. Invest into the future.

max. do 100 bags/min

max. 300 × 400 mm

min. 50 x 60 mm

Machine description

Meet the MS300. Highly flexible, reliable and incredibly fast bagger. Designed for packaging perfection, this bagger combines the ultimate technology, ruggest stainless steel construction and sanitary design. With speeds up to 150 bags per minute, faster, repeatable and accurate production runs will be the standard. Want consistency? The MS300 prevents bottlenecking, assuring all jobs will be steady. Want flexibility? The MS300 accommodates most bag styles, including block bottom, quad-seal and doy-style bags. Want peace of mind? Make the MS300 your next investment. Invest into the future.

Machine features

- Robust, stainless steel frame

- Siemens or Allen Bradley control system

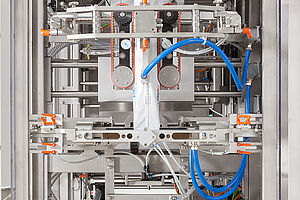

- Servo-drive jaw actuation

- Servo pull belts actuation

- Open frame design

- Quiet running speeds up to 150 bpm

- Off-the-shelf components

- Minimal maintenance requirements

- Short film path

- Small machine footprint

- No tool changeover

- Self-centering pull belts

- Automatic film tracking

- VFD powered film unwind

- Quick film splice table

- Product stagers

- End-seal cooling air

- Bag deflators

- Photo eye and encoder

- Double guard door

- Automatic machine stop

- Jaw obstruction detection

- Runs most film structures

- Siemens control platform

- Storage for 100 product recipes

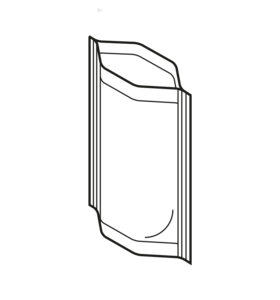

Pillow

Pillow

Gussetted

Gussetted

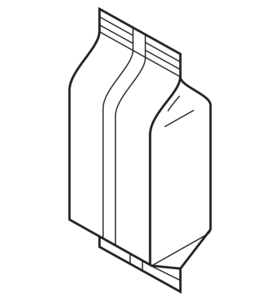

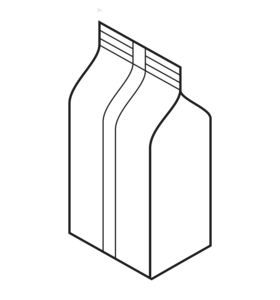

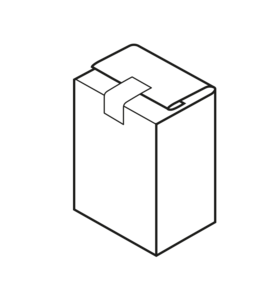

Flat bottom

Flat bottom

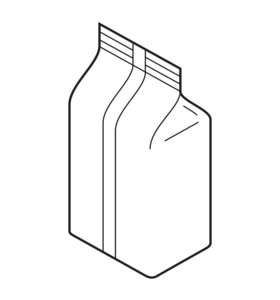

Corner creased

Corner creased

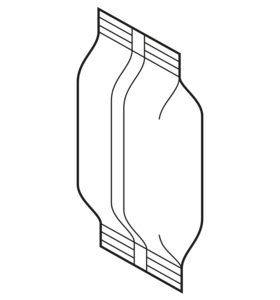

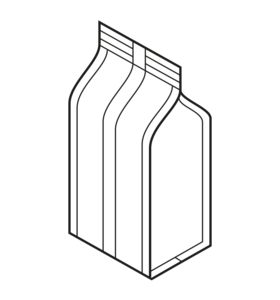

Quad seal

Quad seal

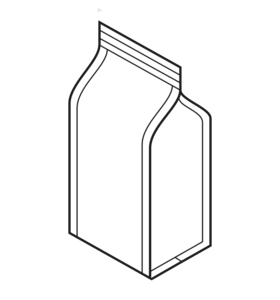

True quad seal

True quad seal

Doy style

Doy style

Double doy

Double doy

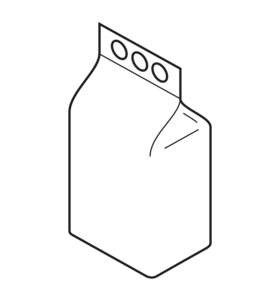

Brick pack

Brick pack

Tetrahedron

Tetrahedron

3-side sealed

3-side sealed

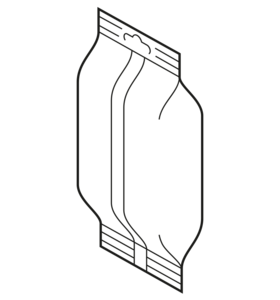

Zip

Zip

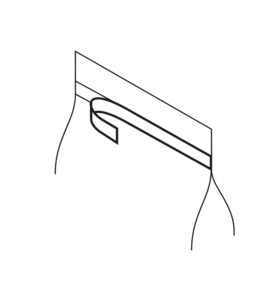

Tin tie

Tin tie

Clip

Clip

Label

Label

Resealable tape

Resealable tape

Finger grip

Finger grip

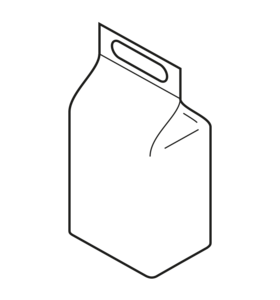

Carry handle

Carry handle

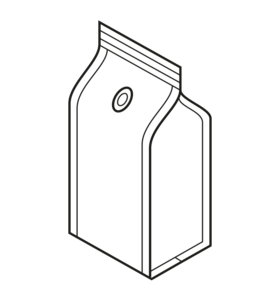

Degassing valve

Degassing valve

Euroslot

Euroslot

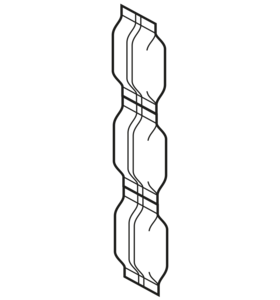

Chain bag

Chain bag

- Ultrasonic sealing jaws

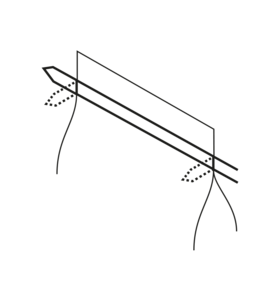

- Quad seal bag assembly integrated in film path

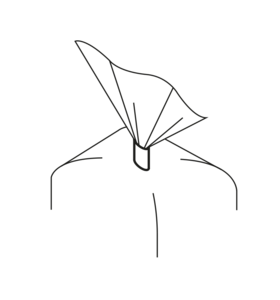

- Doy bag assembly

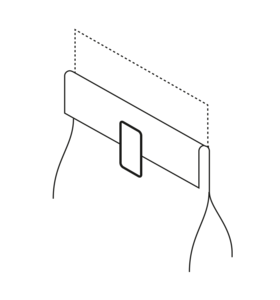

- Flat bottom bag assembly

- Impulse sealing for poly film structures

- Integration with variety of fillers, printers, metal detectors, label applicators, and checkweighers

- Washdown IP66 construction

- Vacuum pull belts

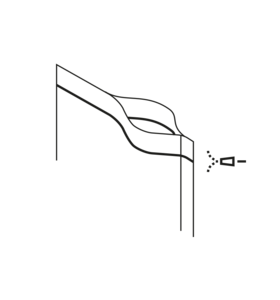

- Fold-down/tape-down unit

- Hole punch (Euroslot and Round)

- Load shelf

- Product settler

- Gas flush

- Static eliminator

- Tear notch

- Degassing valve applicator

- In-feed and take-away conveyors

- Remote diagnostics

- Zipper applicator

- Max. speed: do 100

- Bag width: 60–250 mm

- Bag length: max. 400 mm (jeden potah)

- Weight: 750

- Power supply: 6

- Air pressure: 6

- Air consumption: 0,2

- Air consumption: 150

- Bag size max.: 300 × 400

- Bag size min.: 50 x 60