Multi-line Sachet machine SA300

Looking for speed and flexibility in your sachet needs? Our versatile multi-lane SA600 sachet machines can accomodate from 1 to 6 lanes to form sachet pouches. Designed to pack powders, dense, fine, loose and particulate materials as well as liquids and semiliquids into 4-side sealed sachets and to accomodate different bag shapes including tear notches and easy-open system. Fully automated cartoning solutions are offered to suit your needs.

max. 80 bags/min

max. 250 x 200 mm

min. 40 x 50 mm

Machine description

Looking for speed and flexibility in your sachet needs? Our versatile multi-lane SA600 sachet machines can accomodate from 1 to 6 lanes to form sachet pouches. Designed to pack powders, dense, fine, loose and particulate materials as well as liquids and semiliquids into 4-side sealed sachets and to accomodate different bag shapes including tear notches and easy-open system. Fully automated cartoning solutions are offered to suit your needs.

Machine features

- Powered film unwind with film tention control

- Film slitters and forming tubes - set per bag size

- Discharge chutes

- Siemens or Allen Bradley control system

- Automatic film tracking

- Integrated inner light

- GMP construction

4-side sealed

4-side sealed

- Straight cut

- Zigzag cut

- Die cut

- Multi-lane volumetric filler, servo auger filler or servo liquid fillers

- Easy open features like tear notch or microperforation

- Various seal patterns and shapes

- Offset back seal

- Automatic bag length adjustment

- Individual discharge chutes

- Empty sachet detection

- Empty sachet rejection

- Dust suction nozzles

- Static eliminator

- Film edge trimming and suction (powered)

- Embossing in the longitudinal seal

- Stainless steel construction

- Pharma construction (IQ/OQ)

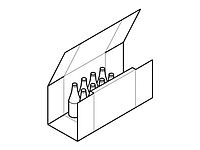

- Robotic pick-and-place unit and automatic cartoning solutions

- Hot stamp, Inkjet, or thermal transfer printer

- In-feed and out-feed conveyors

- Max. speed: 80

- Bag width: 40–250 mm

- Bag length: max. 45-200 mm

- Weight: 1000

- Power supply: 6,8–8

- Air pressure: 6

- Air consumption: 4–10

- Air consumption: 80

- Bag size max.: 250 x 200

- Bag size min.: 40 x 50