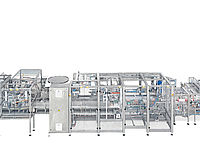

Multi-line Stickpack machine ST600

Looking for flexibility in your Stickpack needs? Our versatile multi-lane ST600 Stickpack machines can accomodate from 1 to 14 lanes to form different shapes of Stickpack pouches. Designed to pack powders, dense, fine, loose and particulate materials as well as liquids and semiliquids into stickpack bags and to accomodate different bag shapes including pour spouts, tear notches and easy-open system. We also offer fully automated cartoning solutions to suit your needs.

max. 80 bags/min

max. 60 x 200 mm

min. 17 x 40 mm

Machine description

Looking for flexibility in your Stickpack needs? Our versatile multi-lane ST600 Stickpack machines can accomodate from 1 to 14 lanes to form different shapes of Stickpack pouches. Designed to pack powders, dense, fine, loose and particulate materials as well as liquids and semiliquids into stickpack bags and to accomodate different bag shapes including pour spouts, tear notches and easy-open system. We also offer fully automated cartoning solutions to suit your needs.

Machine features

- Powered film unwind with film tention control

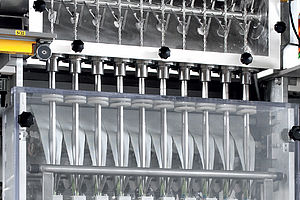

- Film slitters and forming tubes - set per bag size

- Discharge chutes

- Siemens or Allen Bradley control system

- Automatic film tracking

- Integrated inner light

- GMP construction

- Easy change-over™

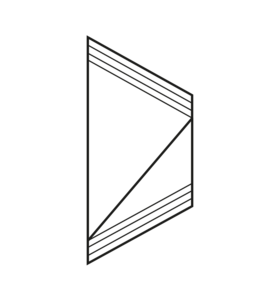

Tetrahedron

Tetrahedron

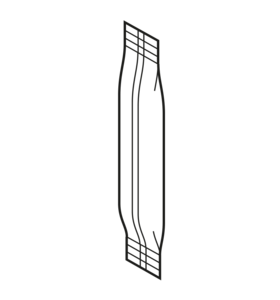

Stickpack

Stickpack

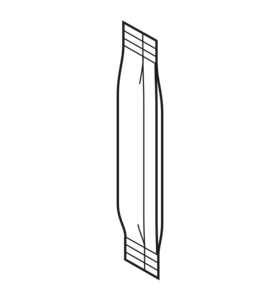

Stickpack side seal

Stickpack side seal

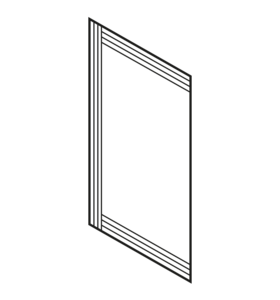

3-side sealed

3-side sealed

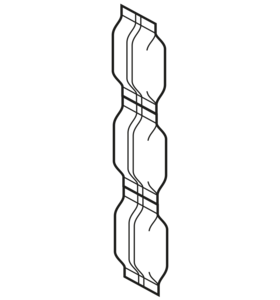

Chain bag

Chain bag

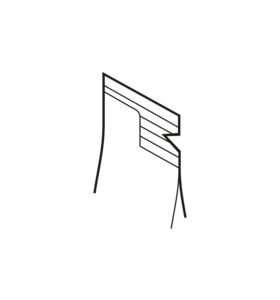

Tear notch

Tear notch

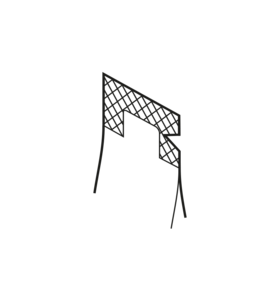

Pour spout

Pour spout

Various cut types

Various cut types

Microperfors

Microperfors

Various seal shapes

Various seal shapes

- Straight cut

- Zigzag cut

- Round cut

- Multi-lane volumetric filler, servo auger filler or servo liquid fillers

- Easy change-over parts and stainless storage cart

- Easy open features like tear notch, microperforation or laser score

- Various seal patterns and shapes

- Offset back seal

- Automatic stickpack length adjustment

- Individual discharge chutes

- Empty stick detection

- Empty stick rejection

- Dust suction nozzles

- Static eliminator

- Film edge trimming and suction

- Embossing in the longitudinal seal

- Stainless steel construction

- Pharma construction (IQ/OQ)

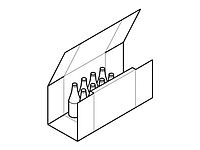

- Robotic pick-and-place unit and automatic cartoning solutions

- Hot stamp, Inkjet, or thermotransfer printer

- In-feed and out-feed conveyors

- Max. speed: 80

- Bag width: 17–70 mm

- Bag length: max. 200 mm

- Weight: 800

- Power supply: 6,5

- Air pressure: 6

- Air consumption: 4–10

- Air consumption: 80

- Bag size max.: 60 x 200

- Bag size min.: 17 x 40